Go Back

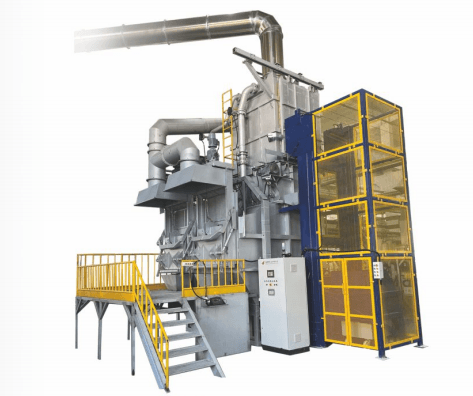

GTJ Aluminium alloy rapid concentrated melting furnace

Compact structure, small footprint, minimal heat dissipation surface, and high thermal efficiency.

More Details

- Adopting a tower structure, the design utilizes an inverted cone shape in the melting chamber and charging tower to position the material blocks at the upper part, allowing full absorption of waste heat from flue gas and thereby significantly saving energy.

- The upper part of the heating tower is designed with an enclosed hood to minimize heat dissipation losses.

- A heat exchange device is adopted to utilize the waste heat from flue gas to preheat combustion air, thereby reducing energy consumption.

- The furnace pressure adopts a micro-negative pressure automatic control system, which not only contributes to energy conservation but also effectively protects vulnerable components such as furnace doors by preventing flame spillage.

- Automatically control the supply of combustion air to prevent incomplete combustion or excess air from carrying away heat, thereby further saving energy consumption.

- Due to the unique structure, the temperature of the molten aluminum flowing out of the melting chamber is relatively higher, reducing the heating requirements for the mirror surface in the holding chamber. This allows the holding capacity of the chamber to be designed smaller, minimizing unnecessary heat retention losses and aluminum oxidation.

- The burner is designed at the furnace top to minimize aluminum splash onto the burner.

- The melting chamber door and holding chamber door are designed on the same side. with the operation platform concentrated on one side, which not only facilitates workshop layout but also further reduces the footprint.

- The charging mechanism features dual-track turning,enabling direct delivery of the charge car into the charging tower, thereby reducing the charging height and mitigating the impact of charge blocks on the furnace lining, while also enhancing the sealing of the furnace hood.

- Due to the rectangular shape of the furnace body, there are no structural weak points, and the thicker plate construction ensures minimal external damage.

- Equipped with a data analysis system, it records the aluminum ingot feed volume and unit energy consumption in real time.